Material Files¶

The material (“mat”) file for Goma contains a description or specification of all the properties required for the multi-physics capabilities of Goma. A separate .mat file must be developed for each material present in each simulation. The mat file (see Figure 5) is split into seven sections: (1) Physical Properties (Section 5.1), (2) Mechanical Properties and Constitutive Equations (Section 5.2), (3) Thermal Properties (Section 5.3), (4) Electrical Properties (Section 5.4), (5) Microstructure Properties (Section 5.5), (6) Species Properties (Section 5.6), and (7) Source Terms (Section 5.7).

Each section in this chapter discusses a separate part of the material file specification and it indicates the data cards or input records that may be used, followed by the options available for each individual record (or line in the file) and the necessary input data/parameters. All input data are specified in a free field format with successive data items separated by blanks or tabs. In this version of the user’s manual, a new format has been instituted in which each record is presented in a template structure. This template has eight parts: 1) a title, which is also the card name, 2) a syntax, which is enclosed in a framed box and shows the proper contents of the card, 3) a Description/Usage section, which presents the user options and descriptions of proper input records, 4) an Example, 5) a Technical Discussion to provide relevant information to help the user understand how to select from among various options or how to properly determine the desired parameters, 6) a Theory to provide an understanding of the physics and mechanics that have been implemented or are being exercised, 7) a FAQs section to present important user experience, and 8) a Reference section to identify citations and/or provide background information to the user. This is a more lengthly but a more complete form for documenting and instructing users of Goma.

The syntax entry denotes a unique string for each input record which Goma parses in the input file. All words in these unique strings are separated by a single white space and because the code parses for these exact strings, the parser becomes case sensitive. The identifying string for a particular specification is followed by an ‘=’ character. Following this character will be all additional data for that record, if any. In the syntax box, this additional data is symbolically represented by one or more variables with some appropriate delimiters. Typically, the user will find a variable called model_name enclosed in curly braces ‘{}’; this would then be followed by a description of specific options for model_name in the Description/Usage section. The curly braces indicate a required input and that the user must select one of the offered options for model_name. Required parameters, if any, for the model option are enclosed in angle brackets ‘< >’, while optional parameters for model_name are enclosed in square brackets ‘[ ]’. Following the ‘=’ character, the user may use white space freely between and among the remaining parameters on the command line.

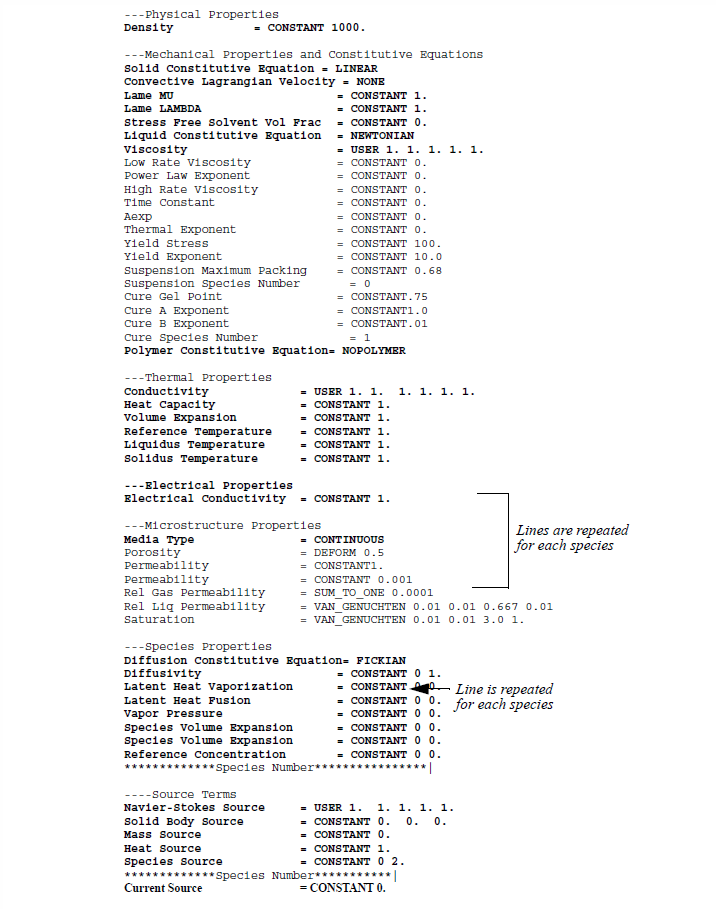

Figure 4 illustrates a typical material file. The section headers, e.g., “— Physical Properties”, are user comments that are not processed by the input parser. In all sections of this chapter, model_name is a character string and floating_point_const_list is a list of floating point numbers of arbitrary length separated by a comma or one or more white spaces. The remainder of this chapter covers each card (line) of the material-description file in detail. For each parameter that is not dimensionless, base units are indicated in square brackets ( [ ] ) at the end of the syntax line; the base units are those indicated in the Nomenclature section of this document. Empty brackets ( [ ] ) denote dimensionless parameters, while those without units or brackets are simply model names, other strings, or integers. Several model parameters, e.g., Diffusivity, where the model options include other than the CONSTANT type with a single input value, identify the units as [varied]. In these cases, the parameter units will be listed for the CONSTANT model option and the units for individual input parameters will be identified in the parameter description.

Sample material-description file format. Lines highlighted in bold-face type are required.¶

All property models will eventually have a USER and a USER_GEN option. When the former is selected, the user must add the user model to the appropriate routine in the file user_mp.c. This file contains a template to simplify the implementation of a model in a full-Newton context, but has the restriction that none of the models can contain a dependence on gradients of variables. For more complex models, which contain such dependencies, the user must resort to the more sophisticated mechanism that comprise the routines in user_mp_gen.c

A relatively new capability/model available on many of the properties is a table-lookup feature. That is, if the model is of type TABLE, then a linear or bilinear interpolation is used to extract the material property value from a table of numbers representing the dependence. The best way to explain this is with an example. Often times a property is dependent on temperature, or related dependent variable. If discrete data is available of the property value at various temperatures, as from a spreadsheet, then such a table can be read and with appropriate interpolation operations the property value is determined. Throughout the material property options, the reader might see aat TABLE option. The syntax for the input of that option is as follows:

<Property name> = TABLE <integer1> <character_string1> [character_string2] {LINEAR | BILINEAR} [integer2] [FILE = filenm]

Here, the integers, character strings and floats are defined as follows:

<integer1> - the number N of columns in the table. The first N-1 columns are the values of the independent variables (e.g. temperature, concentration, etc.) and the final Nth column is the property value. This number is usually 2.

<character_string1> - Required variable name for first column. Valid variable names are TEMPERATURE, MASS_FRACTION, SPECIES, CAP_PRES, FAUX_PLASTIC, and LOWER_DISTANCE. The last three are specific to the Saturation model of porous flow, the LAME Mu model, and the Lubrication Height function model, respectively. Temperature and mass fraction dependence are available in all properties with a TABLE option which make sense.

[character_string2] - Optional second variable name for bi-linear lookup dependence. This is exploratory.

{LINEAR | BILINEAR} - type of interpolation

[integer2] - species number required only for MASS_FRACTION, SPECIES, and FAUX_PLASTICITY variables.

[FILE = <filenm>] - The optional keyword ‘FILE=’ indicates that the table data is to be read from a separate file identified by <filenm>. Each row of the table corresponds to one variable value, and is input in free form CSV or space separated values. Note that if this ‘FILE=’ option is not present then the data will be read from the input material file itself following the TABLE model card. The end of the table is signaled by the keyword “END TABLE” (see example below).

Some examples are in order:

Lame MU = TABLE 2 FAUX_PLASTIC 0 LINEAR FILE=stress_strain_comp.txt

...

Lame MU = TABLE 2 TEMPERATURE LINEAR

1. 293

2. 300

3. 425.

END TABLE

Finally, before we get started, the following is an option added to allow existing Chemkin material property databases to be read in, basically obviating the need to even read the material (mat) file. The detailed description of input records provided in this chapter thus applies to the case when the Default Database is set to GOMA_MAT.